Our high-quality aluminum lips are crafted with precision using 6061 T6 aluminum alloy, a material known for its strength, lightweight properties, and durability. The manufacturing process involves several critical steps to ensure each lip meets our high standards for both performance and appearance.

The process begins with selecting premium 6061 T6 aluminum alloy, known for its excellent strength-to-weight ratio. The alloy is then cut into large plates, which will be shaped into the final form of the lip.

Using a spinning machine, the aluminum plate is carefully spun to achieve the desired lip shape. This process allows for the creation of precise curves and forms, essential for the perfect fit on your wheel.

Once the lip has been spun into shape, it undergoes a heat treatment process known as quenching. The lip is placed in a high-temperature box, where it is heated to a specific temperature and then rapidly cooled. This step significantly enhances the strength and integrity of the aluminum, ensuring the lip can withstand the stresses of driving while maintaining its structural stability.

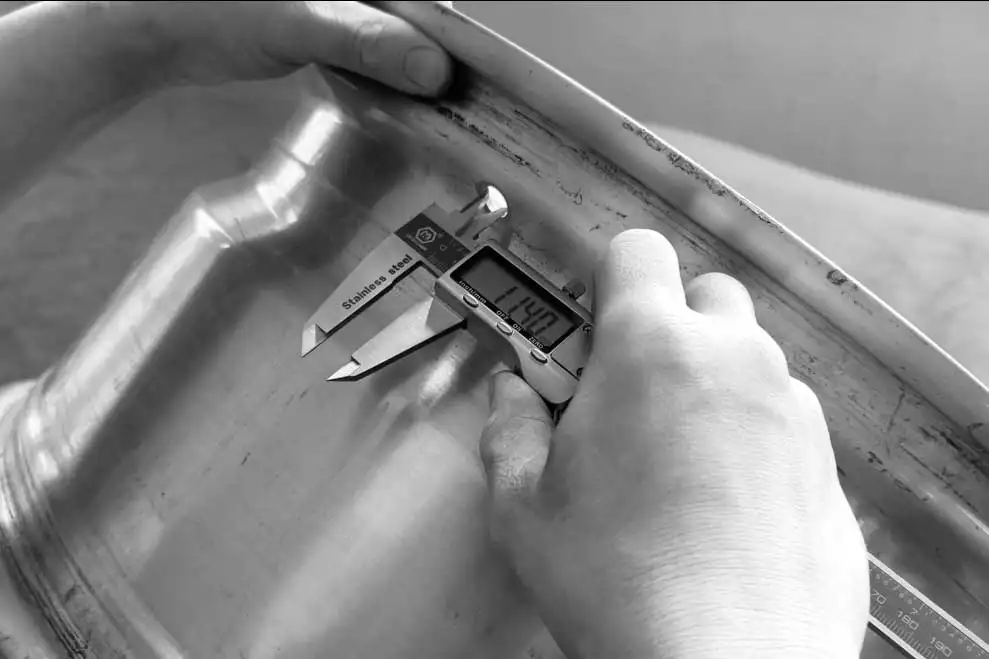

After quenching, the lip is placed in a CNC turning machine where excess material is carefully removed. This step ensures that the thickness and dimensions of the lip are consistent and meet the required standards for strength and fitment. The CNC machine also helps refine the surface, providing a smooth and uniform finish.

To make sure the lip fits securely with the rest of the wheel, the next step involves drilling precise screw holes. These holes are where the lip will be attached to the barrel of the wheel. We use high-quality drill bits to ensure accuracy and prevent any material stress that could affect performance.

Finally, to enhance the appearance and durability of the lip, we perform a surface treatment. The lip is polished to a mirror-like finish, giving it a bright, reflective shine that not only looks stunning but also provides added protection against corrosion. This final touch ensures that our lips look as good as they perform.

From material selection to the final polished finish, every step in the creation of our aluminum lips is focused on delivering exceptional quality and a perfect fit. Whether you’re upgrading your wheels for better performance or customizing them for a unique look, our lips are designed to meet the highest standards of craftsmanship and durability.